This form is the fastest way to contact us for a free consultation, quote and price list request, we will reply you asap.

- Whatsapp: +86 134 6222 7588

- Wechat: +86 134 6222 7588

- E-Mail:sales@dzscreen.com

- Skype: +86 134 6222 7588

Free Shipping

30-Day Returns

5 Days Delivery

Factory Price

After-sales Service

1. Pharmaceuticals : mixing prior to granulation

2. Food processing : premixing, cereals, coffee mixes, dairy powders, vitamin complements, soup, spices.

3. Chemicals : metallic powder mixtures, minerals

4. Construction : steel preblends

5. Plastics : mixing of masterbatches, mixing of pellets

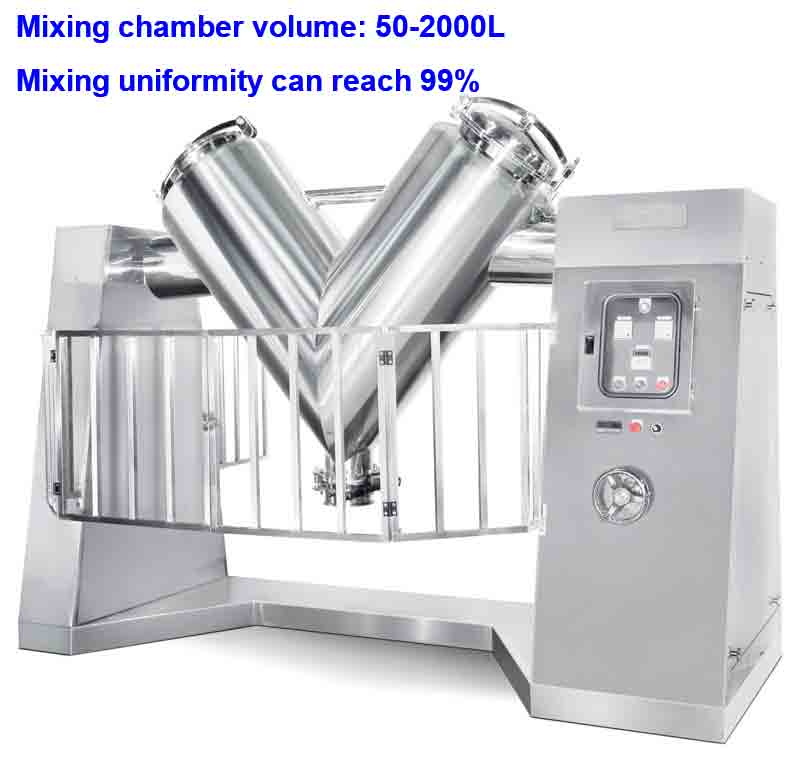

V-Type Mixers are rotary mixers, also called tumble blenders, which are made by rotating a V-shaped container, made of 2 cylinders welded at 75° to 90°, which can be rotated to mix the ingredients by diffusing mixing to achieve fast and uniform mix.

Twin shell blender is suitable for mixing dry powder and granular materials in mines, pharmaceuticals, chemicals, and food.

It can be designed as single or double arms according to customer requirements.

1. Place the machine on a flat and sturdy surface so it will run smoohtly and effciently.

2. Before use, check the gear reducer to ensure there has enough oil.

3. Run an empty load. Check carefully to make sure the machine is under good condition.

4. The materials should not exceed 40% of the cylinder's limit.

5. It is necessary to clean the hopper completely when changing materials or when finishing a run.

1. It is made of stainless steel 304 /316L. Its inner and outer walls are processed through polishing.

2. The cylinder body is made of 2.5mm 304-2B stainless steel material, the outsourcing is made of 1.2mm 304-2B stainless steel material, and the bracket is made of 5# channel steel.

3. The discharge valve is made of all stainless steel, and the connection is sealed with a shaped silicone rubber material to ensure the sealing effect of the machine when it is working.

4. The feed inlet adopts the optional quick opening structure, which makes the user easy to operate when feeding and cleaning.

5. Two stainless steel lead plates are welded at the joints on both sides of the cylinder body and polished, so that there is no dead corner in the cylinder body to ensure that the mixer can achieve the desired effect during mixing and cleaning.

6. There is a forced stirring device in the mixer.

1. Just leave us your WhatsApp or email, we send the latest price list to you.

2. Whenever, 7X24 hours online service is waiting for you.

3. Trust us one time, we will not let you down.

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Sieving Machinery.

Jason

Jason

Whatsapp Contact person

Scan QR Code to Add Contacts

Scan QR Code to Add ContactsOur company can manufacture all kinds of vibration sieves

If you can’t find the one you want

Just tell me, we will send the price list to you soon

This form is the fastest way to contact us for a free consultation, quote and price list request, we will reply you asap.

Copyright © 2012-2023 Xinxiang Dongzhen Machinery Co., Ltd. All Rights Reserved.